COMPLETING INVESTIGATIONS OF COMPLEX MECHANICAL FAILURES REGARDLESS OF SITUATION OR SCALE

Today’s mechanical equipment is increasingly complex. When critical failures arise, they not only have the potential to create massive disruptions and serious injuries, but they frequently include severe economic repercussions. Mechanical equipment fails as a result of issues pertaining to maintenance, end of life, application, commissioning and, in rare cases, manufacturing. Issues may also include an error in the design or implementation of a mechanical technology, which leads to substandard or a complete lack of performance.

Haag Canada has assembled a highly skilled team of experts to conduct investigations into complex mechanical equipment and system failures, from identifying cause to determining remediation and loss mitigation. Whether the focus is to identify and investigate a single contributing factor of a failure or all contributing factors, our experts undertake a comprehensive examination of circumstances and provide a meticulous assessment to help clients confidently determine next steps.

Applicable industries include, but are not limited to buildings, manufacturing, food processing, power generation, district energy systems, mining, oil and gas.

While the Mechanical group supports all of Haag Canada’s five core services, the following outlines specific capabilities across a wide range of technologies, including:

Central utilities

Building Systems

Rotating Equipment/Machinery/Heavy Equipment

Materials

Central Utilities

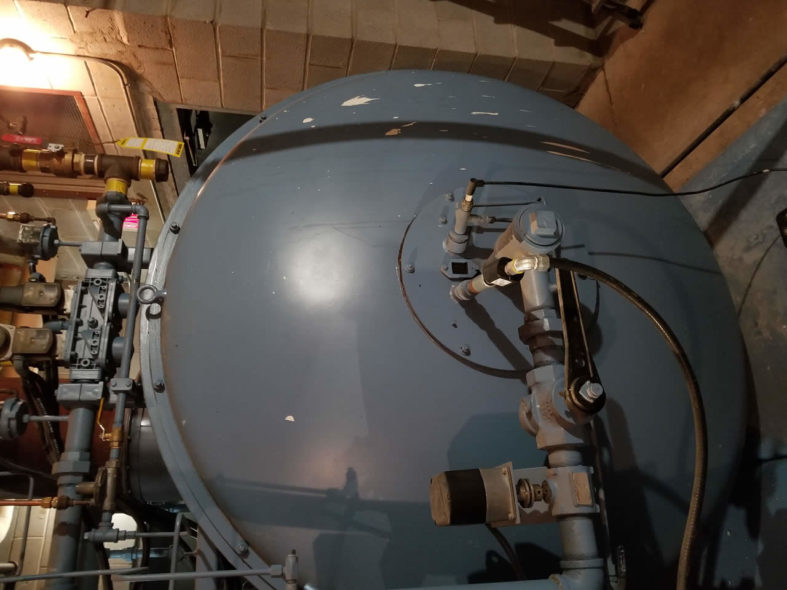

Central utility plants are the heart of most large buildings and building complexes, providing energy, steam and conditioned air. Failure of these systems has significant impacts on owners, occupants and operations. Typical systems include:

- Steam boilers and pressure vessels

- Chillers and refrigeration

- Piping and distribution

- Condensate recovery equipment

- Heat exchangers

Building Systems

Building mechanical systems ensure the comfort and safety of occupants. Failures can lead to excessive noise, mould, mildew, and a range of air quality issues, or more serious outcomes such as fires and floods. Typical building systems include:

- Air handling

- Hydronic heating and cooling

- Domestic water and plumbing

- Sanitary

- Fire protection

- Elevators

- Specialty HVAC (laboratories, clean rooms, isolation suites, operating rooms)

Rotating Equipment / Machinery / Heavy Equipment

As advancements in the industry have enhanced efficiency and automation, mechanical equipment has become more sophisticated, leading to more costly failures. These areas break down into three main categories:

- Rotating Equipment

- Turbines

- Compressors

- Pumps

- Fans

- Motors

- Machinery

- Manufacturing

- Process

- Heavy Equipment

- Cranes and aerial lifts

- Forestry

- Mining and tunnel boring

- Earth moving

Materials

Material failures are ubiquitous throughout mechanical equipment and systems. With remarkable innovations in material science there is a greater potential for failure. Typical materials include:

- Metals

- Concrete

- Plastic polymers

- Crystal /Glass

- Ceramics

- Biomaterials / Nano Technologies

- Insulators and coatings

Experts

Director Forensic Engineering, Forensic Laboratories

Practice Lead – Electrical/Mechanical